SHOCK & VIBRATION TECHNOLOGY

FUNDAMENTALS

What is VIBRATION?

What is SHOCK?

SHOCK & VIBRATION

SHOCK PULSE METHOD

SHOCK PULSE TECHNOLOGY

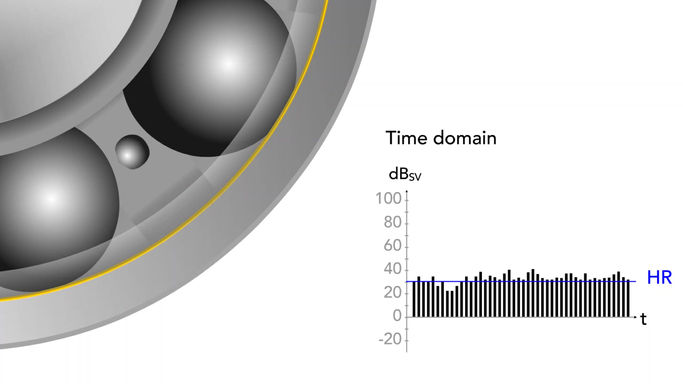

Shock pulses are transient pressure waves generated in every rotating rolling bearing, throughout the bearing’s life.

Their intensity and pattern is directly related to the mechanical condition of the bearing surfaces.

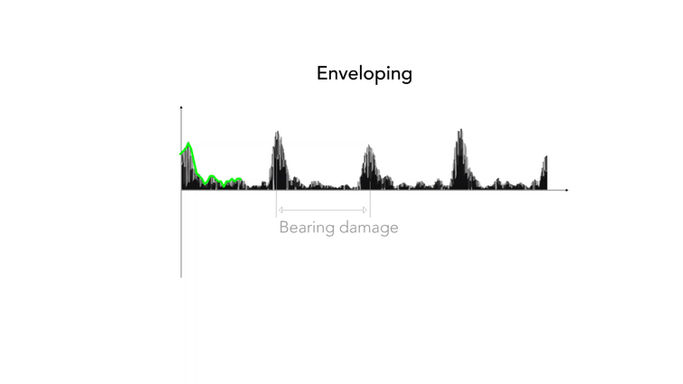

Energy of the shocks produced by a damaged bearing is negligible when compared to the vibration energy at the shaft frequency (rpm).

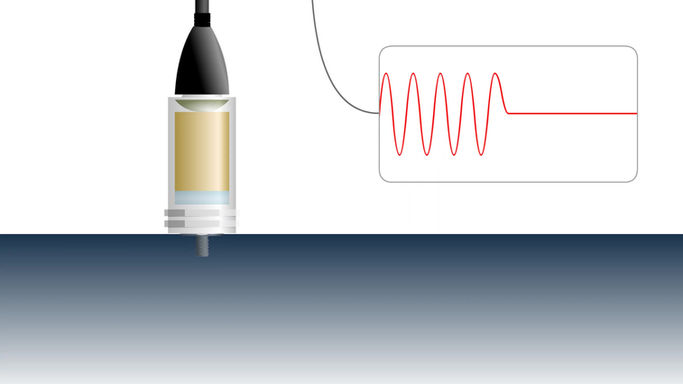

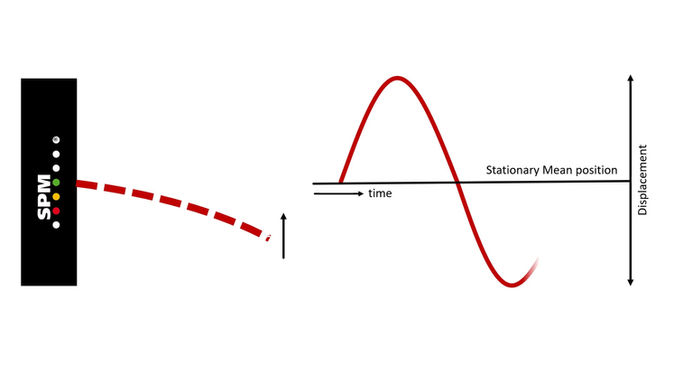

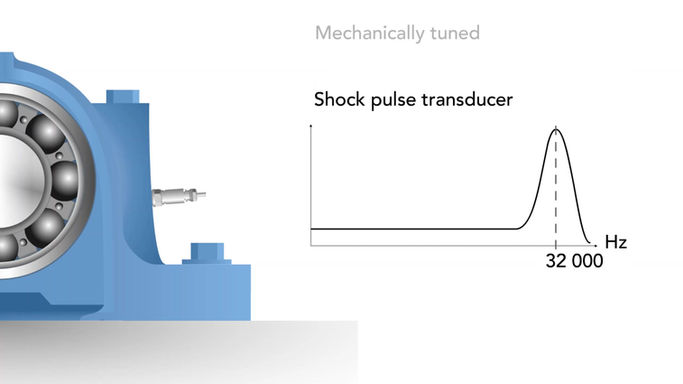

Shock Pulse Technology specializes in Shock detection. Instead of trying to extract these Shock transients from a vibration record as done in regular Vibration technology, Shock Pulse technology uses a special transducer and measuring circuit to measure the Shocks directly in the time domain as generated from the Bearing.

This makes Shock Pulse Measurement the most sensitive and powerful method for Bearing condition monitoring, enabling the earliest identification of Bearing abnormalities. It also helps identify insufficient lubrication film thickness so that lubrication can be corrected in time to avoid Bearing damage.

CONDITION SHOCK PULSE Pattern & Intensity

GOOD Bearing

SUFFICIENT Lubrication film

GOOD Bearing

INSUFFICIENT Lubrication film

DAMAGED Bearing

SHOCK PULSE Fundamentals

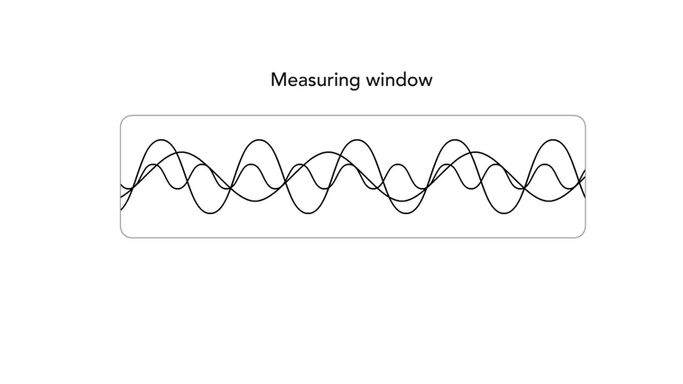

Difference betwen Shock & Vibration

TRANSDUCER: Shock

SHOCK PULSE dBm/dBc